Thermographic Testing (TT)

Thermography allows an extensive investigation of composite structures to identify inhomogeneities, voids, delaminations in the first layers of the laminate, presence of humidity.

It is a non-destructive analysis technique based on the acquisition of infrared images. An IR thermographic system consists of a camera connected to an image processing and recording system.

All objects at a temperature above absolute zero emit radiation in the infrared range. The use of thermography allows the reading of the radiations emitted in the infrared band by bodies subjected to thermal stress. The radiant energy is a function of the surface temperature of the materials, conditioned by the thermal conductivity and the specific heat, which express in quantitative terms the aptitude of the material itself to transmit the heat or retain it: a material with high conductivity values it will quickly heat up and just as quickly cool down.

Due to the different values of these parameters, specific for each material, the different components of a product will have different temperatures under the action of thermal stresses. This characteristic is exploited by thermography to visualize the different thermal behavior of the materials.

The amount of radiation emitted increases proportionally to the fourth power of an object’s absolute temperature.

The correlation between radiation and temperature is provided by the Stefan-Boltzmann Law:

q = ε z S T 4

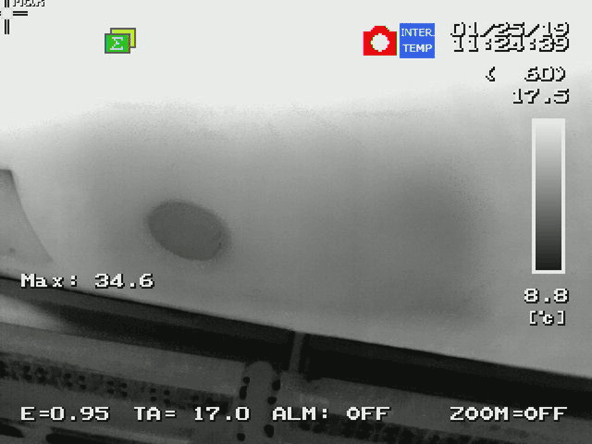

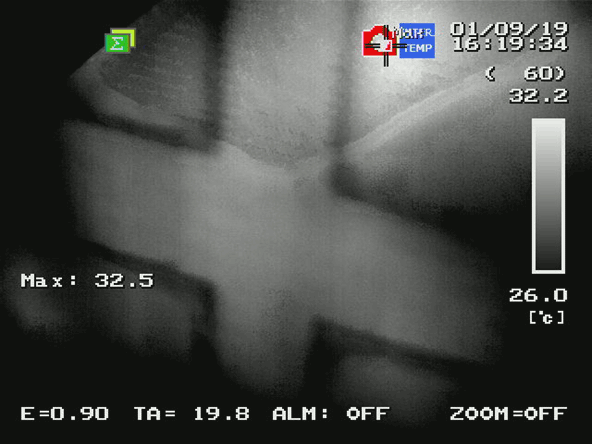

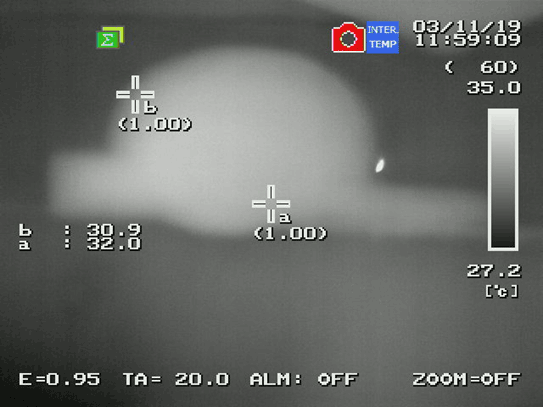

Below some examples.

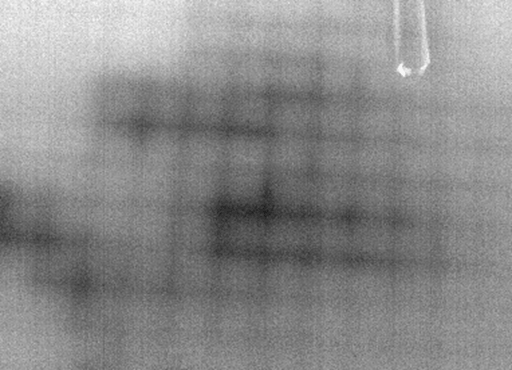

Sandwich panel: core is correctly bonded to the skin, cuts in the foam are clearly visible.

Sandwich panel with water trapped in the cuts of the foam

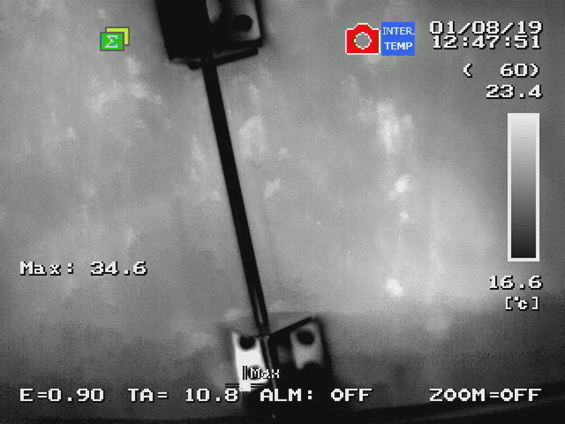

Outer voids in the laminate of transom

Single skin insert in a sandwich panel

Sandwich panel with different core materials

Sandwich panel with an insert with different core material